Apogee Silver Announces 106% Increase in Indicated Silver Resources at Its Pulacayo Silver-Lead-Zinc Deposit

TORONTO, ONTARIO–(Marketwire – Sept. 28, 2012) – Apogee Silver Ltd. (“Apogee” or the “Company“) (TSX VENTURE:APE) is pleased to report the results of a National Instrument 43-101 compliant independent mineral resource estimate on the Pulacayo Deposit located in southwestern Bolivia (Figure 1), which includes a total of 60.3 million ounces of silver in the Indicated category and a total of 9.2 million ounces of silver in the Inferred category, as detailed in Table 1 below.

This mineral resource estimate represents an increase in silver in the Indicated resource category of 106% or 30.9 million ounces from the mineral resource estimate dated October 19th, 2011 and supported in the NI 43-101 Technical Report dated May 23rd, 2012 and filed under the Company’s profile on SEDAR (See Press Releases dated October 18th, 2011, and May 23rd, 2012). This increase is comprised of a 45% increase in the Indicated category from underground sulphide resources, with an additional 13.2 million ounces of silver from 6.19 million tonnes grading 213.6 grams/tonne silver, 0.86% lead and 1.74% zinc. It also includes an additional 4.63 million ounces of silver in the Indicated category from the oxide zone at Pulacayo, with 1.5 million tonnes grading 95.9 g/t silver and 13.17 million ounces of silver in the Indicated category from open pit sulphide resources with 9.28 million tonnes grading 44.1 grams/tonne silver, 0.66% lead and 1.32% zinc.

Neil Ringdahl, Chief Executive Officer, commented that “The new resource estimate continues to demonstrate our confidence in the development strategy for the Pulacayo polymetallic deposit. We look forward to the completion of the feasibility study before the end of 2012 which will provide the road map for the next phase of development of the company’s flagship asset.”

Chris Collins, P. Geo, President commented, “We are particularly encouraged by the increase in silver ounces reported in the Indicated category from the underground sulphide zone. This is due to increased confidence in the detailed geological model as well as an enhanced understanding of the historical mining at Pulacayo developed from the knowledge gained from the engineering initiatives associated with trial mining and the ongoing feasibility study. Further, the disclosure of the oxide and sulphide resources from a potential open pit at Pulacayo is also a very important milestone for the company and we are now ready to proceed to the next stage in evaluating the potential for integrating these resources into the Pulacayo development plan.”

Table 1: Summary of Mineral Resources

Pulacayo Deposit effective date September 28, 2012

| Table 1: Summary of Mineral Resources | ||||||||

| Pulacayo Deposit effective date September 28, 2012 | ||||||||

| Resource Class | Type | Tonnes | Ag g/t | Pb % | Zn % |

Ag

(Oz) |

Pb

(M. lbs.) |

Zn

(M. lbs.) |

| Combined Open Pit and Underground Resources including Oxide and Sulphide Zones | ||||||||

| Open Pit Resources (Base case 42° Average Pit Wall Slope Angle) | ||||||||

| Open Pit Indicated | Oxide | 1,500,000 | 95.9 | 0.96 | 0.13 | 4,626,000 | ||

| Open Pit Inferred | Oxide | 248,000 | 71.2 | 0.55 | 0.31 | 569,000 | ||

| Open Pit Indicated | Sulphide | 9,283,000 | 44.1 | 0.66 | 1.32 | 13,168,000 | 135.9 | 269.54 |

| Open Pit Inferred | Sulphide | 2,572,000 | 33.4 | 0.92 | 1.36 | 2,765,000 | 51.99 | 76.88 |

| Waste Rock | 71,679,000 | Strip Ratio 5.3 : 1 | ||||||

| Underground Resources (all blocks below 4159 m ASL with NSR > $US 58 ) | ||||||||

| Underground | Sulphide | 6,197,000 | 213.6 | 0.86 | 1.74 | 42,547,000 | 117.5 | 237.72 |

| Indicated | ||||||||

| Underground Inferred | Sulphide | 943,000 | 193.1 | 0.43 | 1.61 | 5,853,000 | 8.94 | 43.47 |

| Total Indicated | Oxide + Sulphide | 16,980,000 | 110.5 | 0.74 | 1.49 | 60,341,000 | 253.4 | 507.26 |

| Total Inferred | Oxide + Sulphide | 3,763,000 | 75.9 | 0.79 | 1.43 | 9,187,000 | 60.93 | 120.35 |

NOTES

1. Tonnages have been rounded to the nearest 1,000 tonnes. Average grades may not sum due to rounding.

2. Metal prices used were $25.00 USD/Oz silver, $0.89USD/lb lead, and $1.00 USD/lb zinc. Lead and zinc do not contribute to revenue in the oxide zone.

3. Open Pit Sulphide Resources are reported a $13.20 USD NSR cut-off. Underground Sulphide Resources are reported at a $58USD NSR cut-off. Open Pit oxide resources are reported at a $US 23.10 revenue/tonne cut-off.

4. Contributing 1.0 meter assay composites were capped at 1500 g/t Ag, 15% Pb, and 15% Zn.

5. Specific gravity is based on an interpolated inverse distance squared model.

6. Mineral resources that are not mineral reserves do not have demonstrated economic viability. The estimate of mineral resources may be materially affected by environmental permitting, legal, title, taxation, sociopolitical, marketing, or other relevant issues.

The Pulacayo Deposit was the second largest silver mine in the history of Bolivia with historical estimates of over 600 million ounces past production of silver. The extent of the known mineralization at Pulacayo is based on the extent of the known workings which occur over a strike length of approximately 2.7 kilometers and to a vertical depth of approximately 1 kilometer from surface. To date the Company has systematically drilled approximately 1.5 kilometers of the known strike extent and to a vertical depth of approximately 600 meters from surface (Figure 2). The Pulacayo resources remain open for further expansion at depth and along strike. Apogee is currently focused on the completion of the feasibility study on the development of an integrated underground mine and processing plant at Pulacayo which is scheduled for completion by December 2012 (See Press Release dated May 29, 2012).

Resource Estimate Details:

This updated Mineral Resource Estimation was completed by Mercator Geological Services Limited (Mercator) of Dartmouth, Nova Scotia in accordance with Canadian Securities Administrators National Instrument (“NI 43-101”) and is based on CIM standards. The effective date of this mineral resource estimate is September 28, 2012.

The estimate is based on validated results of 69,739 meters of diamond drilling and 606.34 meters of surface trenching carried out by Apogee Silver through various programs between 2006 and 2012. This includes 226 surface drill holes, 42 underground drill holes, and 6 surface trenches. Modeling was performed using Gemcom Surpac® 6.3 modeling software with silver, lead and zinc grades estimated independently by inverse distance squared (ID2) interpolation from 1.0 meter down hole assay composites capped at 1500 g/t, 15%, and 15% respectively. Block size was 5 meters (x) by 3 meters (y) by 3 meters (z) with one unit of standard sub-blocking allowed. Block model results were checked using ordinary Kriging and Nearest Neighbour interpolation methods.

Sectional interpretations were developed correlating zones of veining with higher grade mineralization for each metal and were subsequently wire-framed into three-dimensional solid models. A total of 9 domains were created for each metal, ranging from a few meters to tens of meters in thickness, within a strike length of 1,500 meters oriented at 280° and 600 meter sub-vertical dip extent. A peripheral wireframe was developed enveloping all metal domains and a digital terrain model of the oxide-sulphide zone boundary was created.

Grade interpolation was first performed for each metal within the respective metal domain wireframes using multiple search ellipsoids that accommodated the local variations in mineralization trends. Interpolation was subsequently performed for each metal outside the respective metal domain wireframes and within the peripheral constraining envelop using similar search ellipsoid orientation parameters. Contributing 1 meter down-hole composites were constrained to a minimum of 2 and a maximum of 9 with no more than 3 from a single drill hole. The oxide-sulphide zone digital terrain model functioned as a hard boundary in all interpolation passes.

A specific gravity model was interpolated by ID2 methodology from 1.0 meter down hole specific gravity composites using the grade interpolation parameters for each metal.

Indicated Resources are all interpolated blocks with at least 7 contributing assay composites with a maximum average distance of 70 meters, with the nearest contributing composite at 60 meters or less. Inferred Resources are all other interpolated blocks within the peripheral constraint. An upgraded model of the historic underground mining and stoping was digitally compiled from the archived mine engineering plans and was used to remove the previously mined blocks from the resource model.

Net Smelter Return (NSR) values for the blocks occurring within the sulphide zone were determined by means of a net smelter calculator developed for the Pulacayo Deposit by John Starkey, P. Eng., of Starkey & Associates Inc., Consulting Metallurgical Engineers of Oakville Ontario. The modeling used a 36 month trailing average silver price of $25.00 USD/oz. The base metal prices used in the modeling were $0.89 USD/lb lead and $1.00 USD/lb zinc. The base metal prices were supplied by Exen Consulting Ltd. of Oakville, Ontario and are based upon the average long-term analyst lead and zinc price projections from a number of metal broker and mining investment banking sources. Exen Consulting Ltd. is in the commercial concentrate marketing business providing consulting services to mine producers, metal traders and smelters around the world.

Open pit resources to an elevation of 4,159m ASL (top of crown pillar) were determined within a Whittle optimized maximum NPV pit shell utilizing $1.80 USD/tonne mining cost, $1.60 USD/tonne surface haulage cost, $2.50 USD /tonne G&A, and $19.0 USD/tonne and $9.10 USD/tonne respectively for oxide and sulphide processing costs. Pit slopes varied from 42 to 43 degrees. In the pit optimization process, only silver derived NSR values were used in the oxides, while silver, lead and zinc derived NSR values were used in the sulphides.

The Company expects to file the full NI 43-101 compliant technical report on the Pulacayo Deposit describing in detail, among other things, the resource estimate, QA/QC, database validation and geologic model, by November 12, 2012.

Independent Qualified Persons:

Peter Webster P. Geo. and Michael Cullen M .Sc. P. Geo. of Mercator Geological Services Limited are independent Qualified Persons, as defined in NI 43-101 who are responsible for the Mineral Resources Estimate and have reviewed and approved the mineral resource estimate section of this press release.

Eugene Puritch P. Eng. of P & E Mining Consultants Incorporated is an independent Qualified Person as defined in NI 43-101 and is responsible for the Open Pit Optimization and has reviewed and approved the scientific and disclosure of this news release as it related to the open pit optimization.

Net Smelter Return

Net Smelter Return is the calculated potential revenue which is returned from the smelter for the sale of concentrate products. The NSR method recognizes that more than 1 metal, (i.e. Ag, Pb, Zn,) can contribute to a potential revenue stream. It proceeds to derive a potential revenue value that accounts for such items as recovery to concentrate, metal prices, payable fractions of the metals treatment, and refining charges, penalties, freight and handling. By this means in situ grades can be converted to potential revenues, with the cut-off grade being the estimated cost of all activities related to mining, mineral processing and general administration.

Quality Control

Apogee Silver employs a QA/QC protocol on all aspects of its diamond drill core processing and analytical procedures. Core samples are sawn and one half of the NQ and/or HQ core is returned to the core box for future reference with the other half sent for analysis. Sample preparation is completed at the ALS Chemex preparation laboratory in Oruro, Bolivia and analysis occurs at the ALS Chemex laboratory in Lima, Peru.

The company’s quality control protocol includes the insertion of certified geological standards which have been purchased from Canadian Resource Laboratories of Langley, British Columbia. Standards are inserted at a frequency of 1 in every 20 samples. The company also inserts geological blanks which are blind to the laboratory at a frequency of 1 in every 20 samples. Duplicates are taken at every sub-sampling stage in the preparation process. Field duplicates are taken at a frequency of 1 every 50 samples. Sample preparation duplicates are taken at the crushing and pulverizing stages at a frequency of 1 in every 20 samples. Cross-check analysis on the master pulps is undertaken at a second laboratory for 5% of all samples. The company uses SGS Mineral Services in Lima, Peru for the second lab cross check analysis.

The Quality Control and all aspects of the exploration program are directed under the supervision of Mr. Chris Collins, P. Geo. and President of Apogee. The scientific and technical information presented in this press release has been reviewed and approved by Chris Collins, P. Geo., President of Apogee Silver and a qualified person, as defined by NI 43-101.

For detailed project information please refer to Apogee’s web site at www.apogeesilver.com.

About Apogee Silver Ltd.

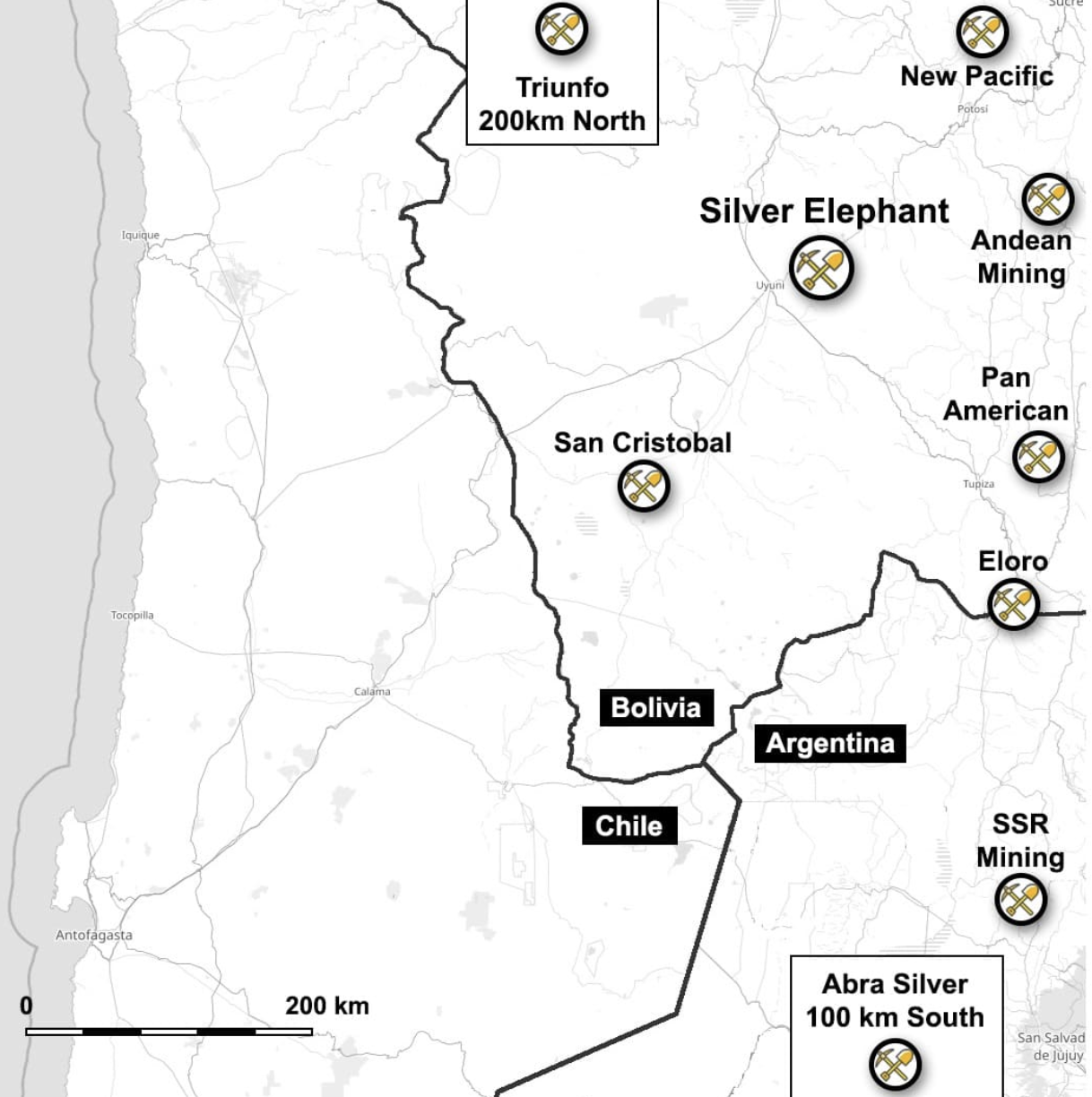

Apogee Silver Ltd. is a mineral exploration and development stage company listed on the TSX Venture Exchange under the symbol APE. Apogee targets advanced silver-zinc-lead projects in South America that demonstrate potential to be developed to production. Currently its projects are located in the historic silver producing regions of southwest Bolivia and northern Chile.

Its most advanced project is the 100% owned Pulacayo-Paca project in Bolivia, This project includes the property that covered the second-largest silver mine in the history of Bolivia with over 600 million ounces of past production.

Cautionary Note Regarding Forward-Looking Information. This press release contains “forward looking information” within the meaning of applicable Canadian securities legislation. Forward looking information includes, but is not limited to, statements with respect to mineral resource estimates, mineral prices, exploration and development timetables and budgets, permitting and future production scenario’s. Generally, forward looking information can be identified by the use of forward-looking terminology such as “plans”, “expects” or “does not expect”, “is expected”, “budget”, “scheduled”, “estimates”, “forecasts”, “intends”, “anticipates” or “does not anticipate”, or “believes”, or variations of such words and phrases or state that certain actions, events or results “may”, “could”, “would”, “might” or “will be taken”, “occur” or “be achieved”. Forward-looking information is subject to known and unknown risks, uncertainties and other factors that may cause the actual results, level of activity, performance or achievements of the Company to be materially different from those expressed or implied by such forward-looking information, including but not limited to: financing not being available at desired prices; general business, economic, competitive, political and social uncertainties; the actual results of current exploration activities; timing and availability of external financing on acceptable terms; conclusions of economic evaluations; changes in project parameters as plans continue to be refined; future prices of mineral prices; failure of plant, equipment or processes to operate as anticipated; accidents, labour disputes and other risks of the mining industry; and, delays in obtaining governmental approvals or required financing or in the completion of activities. Although the Company has attempted to identify important factors that could cause actual results to differ materially from those contained in forward-looking information, there may be other factors that cause results not to be as anticipated, estimated or intended. There can be no assurance that such information will prove to be accurate, as actual results and future events could differ materially from those anticipated in such statements. Accordingly, readers should not place undue reliance on forward looking information. The Company does not undertake to update any forward-looking information, except in accordance with applicable securities laws.

On Behalf of the Board,

| Neil T. Ringdahl | G. Scott Paterson |

| Chief Executive Officer | Chairman |

To view Figure 1, please visit the following link: www.prophecycoal.com/apogee/pdf/ape0928fig1.pdf

To view Figure 2, please visit the following link: www.prophecycoal.com/apogee/pdf/ape0928fig2.pdf

To view Figure 3 Apogees Silver Ltd Bolivia and Chile Project Locations, please visit the following link: www.prophecycoal.com/apogee/pdf/ape0928fig3.pdf

To view Figure 4 Apogees Silver Ltd Bolivia and Chile Project Locations, please visit the following link: www.prophecycoal.com/apogee/pdf/ape0928fig4.pdf

NEITHER THE TSX VENTURE EXCHANGE NOR ITS REGULATION SERVICES PROVIDER (AS THAT TERM IS DEFINED IN THE POLICIES OF THE TSX VENTURE EXCHANGE) ACCEPTS RESPONSIBILITY FOR THE ADEQUACY OR ACCURACY OF THIS RELEASE.

Contact: Marilia Bento

Company Name: Apogee Silver Ltd.

Contact Title: Vice President Corporate Development

Phone: +1 (416) 309-2694

Other1: info@apogeesilver.com

Contact: Neil T. Ringdahl

Company Name: Apogee Silver Ltd.

Contact Title: Chief Executive Officer

Phone: +1 (647) 339-4484

Other1: info@apogeesilver.com

Other2: www.apogeesilver.com